Crowntyre brands are legally registered in over 73 countries across six continents, which provides legal certainty as well as driving marketing synergies for distribution partners, facilitating success in the long run.

Crowntyre brands are legally registered in over 73 countries across six continents, which provides legal certainty as well as driving marketing synergies for distribution partners, facilitating success in the long run.

UHP Series

Touring Series

Highway SUV Series

4x4 A/T Series

Ice Grip Series

Light Commercial Series

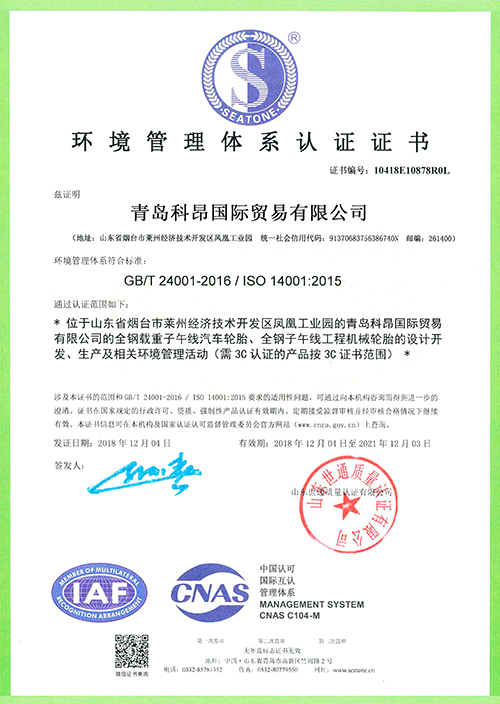

Crowntyre strives to achieve prosperity and customer satisfaction through continual improvement in product quality. The certifications we have received at various steps of our journey are powerful motivators in our uncompromising quest for excellence.

All our manufacturing plants are ISO 9001:2015 certified. We proudly conform to IATF-16949:2016 standards, carry out internal and global product tests including S.G.S and Smithers, and meet international standard requirements of each market: CCC for China, ECE for EU countries, DOT for United States, INMETRO for Brazil, NOM for Mexico, LATU for Uruguay, GSO/GCC for Gulf countries, SASO for Saudi Arabia, SONCAP for Nigeria, SNI for Indonesia, and BIS for India.

ISO 9001 is defined as the international standard that specifies requirements for a quality management system (QMS). ISO 9001:2015 is an updated revised version that includes requirements for a new, higher level structure as a common framework to all ISO management systems, risk-based thinking in quality system processes, fewer prescribed requirements with less emphasis on documentation, clear definition of quality management system boundaries and increased leadership requirements.

An ISO Technical Specification which integrates existing American and European automotive quality management systems standards within the global automotive industry. It is a fundamental proof of product and process quality, providing additional confidence for global sourcing, as well as improving business efficiency and productivity. The standard incorporates QS 9000 (United States), EAQF 94 (France), VDA 6 (Germany), AVSQ ‘94 (Italy), and SMMT (United Kingdom).

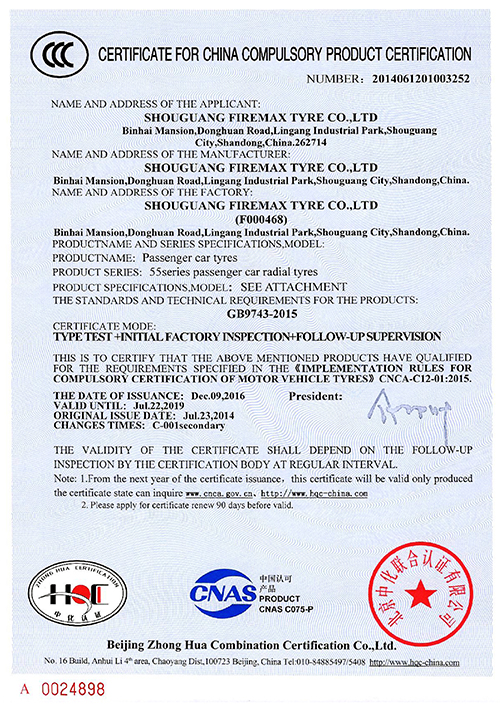

A mandatory requirement for both domestically manufactured products and products imported into China. It serves as a safeguard to the consumers rights, interests, and protect personal and property safety. The mark confirms that the product complies with the applicable legislation and is tested accordingly. Factory inspection is also involved.

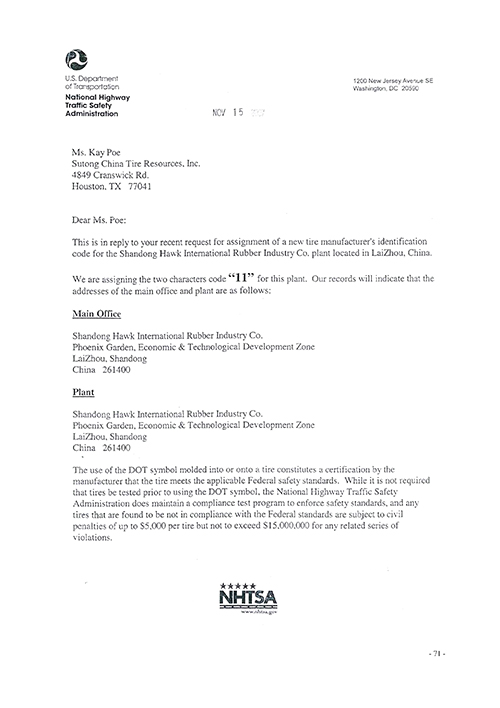

Short for U.S. Department of Transportation, the DOT number is used for safety standard certification in the United States. It indicates the tyre manufacturer's compliance with the U.S. Department of Transportation (DOT) National Highway Traffic Safety Administration (NHTSA) safety standards, and that the tyre has passed the Department of Transportation’s testing and NHTSA manufacturer requirements.

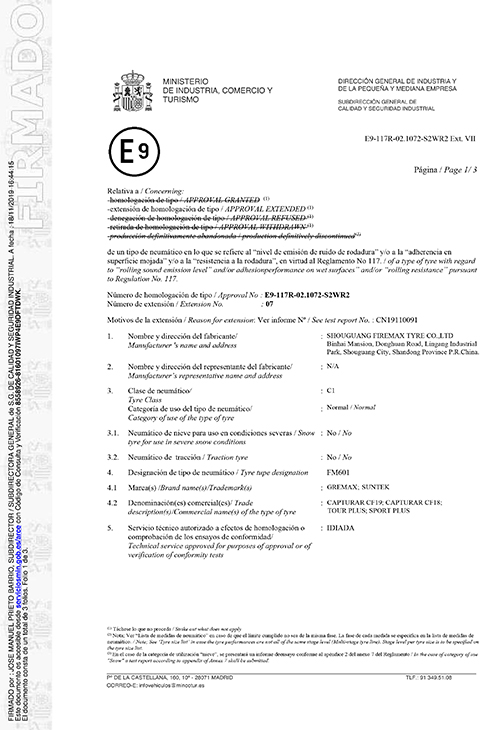

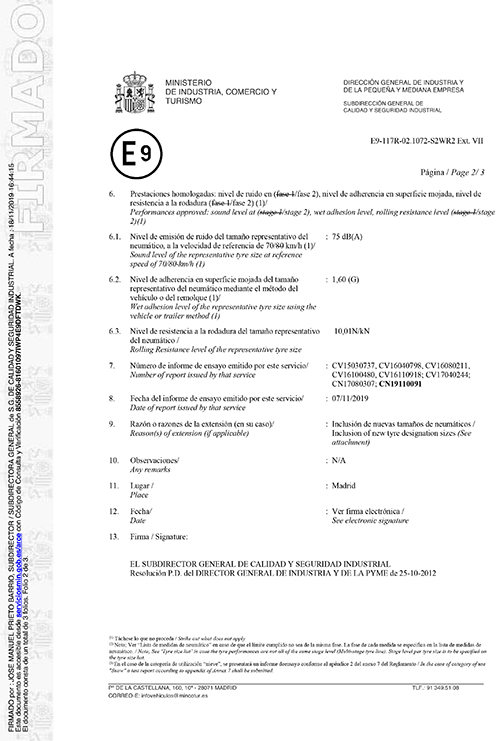

Introduced by the Economic Commission for Europe, E-mark certifies that the tyre has been approved for use in Europe, and signals that the tyre has met certain sizing, performance and marking requirements.All our products are E-marked and road legal in Europe with ECE R117 certifications respectively, a test regarding the tyre noise, wet grip performance, rolling resistance, and snow performance.

Certification of Conformity of Production, evidencing the ability to produce a series of products that exactly match the specification, performance and marking requirements outlined in the type approval documentation.

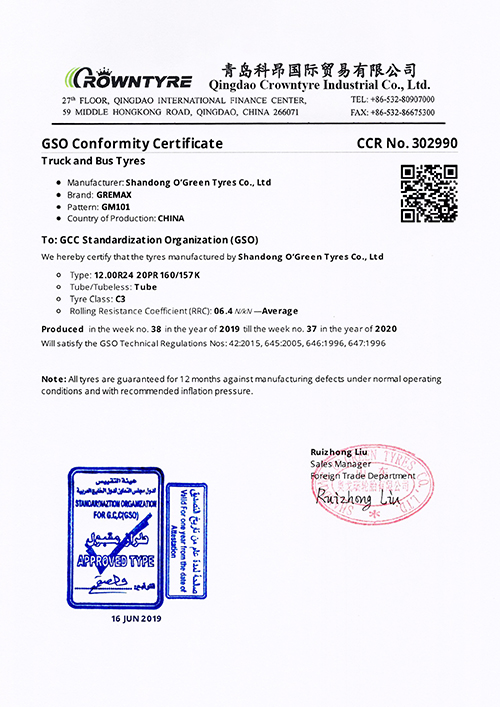

Implemented by GCC Standardization Organization (GSO), the GCC Conformity Certificate (GCC) for tyres is verified and approved as a common Gulf Country Standard for new tyres, applicable to Saudi Arabia, Kuwait, the United Arab Emirates, Qatar, the Sultanate of Oman, the Kingdom of Bahrain and Republic of Yemen. Conformity assessment involves a set of processes that show the product meets specific requirements, which is a competitive edge that provides consumers and other stakeholders with added confidence.

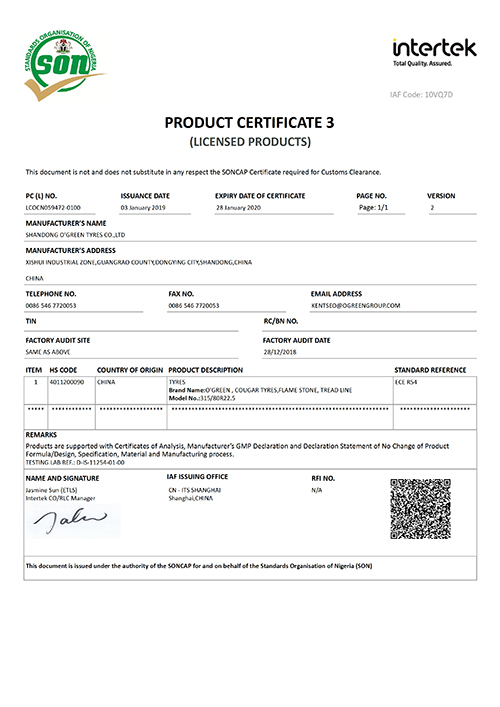

SONCAP is a pre-shipment verification of conformity to Standards process used to verify that products to be imported into Nigeria are in conformity with the applicable NIS or approved equivalents, and technical regulations before shipment.

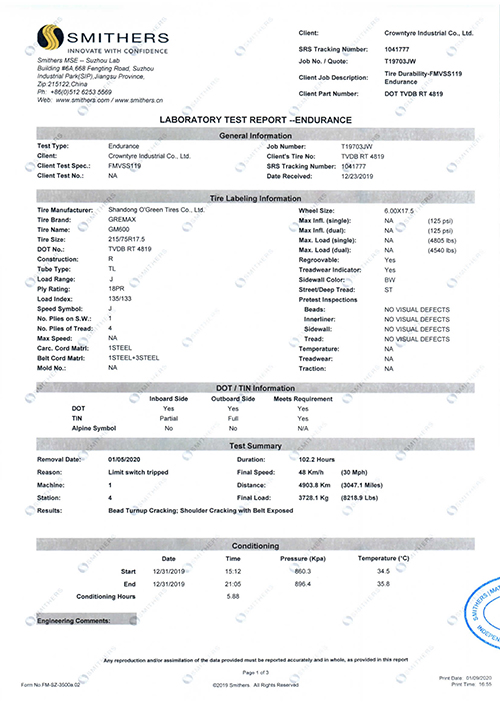

Extensive physical testing report of tyres supported by compound development, analysis and a full failure analysis service. It offers unbiased reporting on durability and endurance, strength, measurements and labellings regarding braking traction, wear life, and pass-by noise level.

Sustainability is our core goal at Crowntyre. We advocate a clean energy, zero-emission, zero-waste future for everyone. Our tyres are manufactured using energy efficient and eco-friendly materials and technologies. We are also passionate about developing tyres for hybrid and electric vehicles to help reduce CO2 emissions.

Crowntyre is devoted to further reduce toxic materials in tyres to improve the safety of products, as well as to minimise potentially toxic chemicals from entering our environment.

Being top of the reliable brands in the market, Gremax, Suntek and Xcellent are manufactured in compliance with the highest regulatory certifications. To comply with stringent European standards, PAH-free oils are utilised in their compounds, while the use of materials with SVHCs are reduced to the minimum. In addition to this, the brands have always been committed to being socially responsible and has been carbon neutral from the beginning.

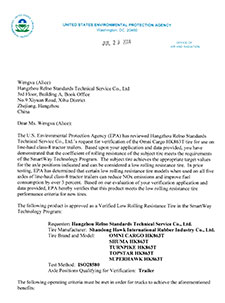

EPA-designated SmartWay tyres significantly lower fuel consumption and emissions of air pollutants. These are verified Low Rolling Resistance Tyres that have been tested and validated to ensure top performance, available for steer, drive, and trailer positions.

Low rolling resistance tyre technologies can reduce both costs and emissions for long-haul tractor-trailers by 3% or more. When used in combination, these tractors and trailers can achieve fuel savings of about 15% to 20% over standard models.

Tyres from Crowntyre are, unless stated otherwise, warranted against workmanship and material or design related conditions throughout their first tread life (new tyres) down to the local official remaining useable tread depth for a certain period of time.